Deep-sea aquaculture has emerged as a crucial solution to meet the increasing global demand for seafood while reducing the pressure on wild fish stocks and coastal ecosystems. As the industry progresses, the quality and performance of equipment, especially netting materials, play a pivotal role. Haosail Machinery’s high-definition alloy netting is making waves in the field, offering a range of benefits that can revolutionize deep-sea aquaculture.

Superior Anti-Biofouling Properties

One of the most significant challenges in deep-sea aquaculture is biofouling. Traditional nylon nets often suffer from the accumulation of algae, barnacles, sea anemones, and other marine organisms. This not only reduces the water flow through the net, decreasing oxygen levels inside the cage but also increases the weight of the net, putting extra stress on the mooring system. In contrast, Haosail’s alloy netting has inherent anti-biofouling properties. Copper-based alloys, which are commonly used in the netting, have been proven to inhibit the growth and attachment of these organisms. For example, in a study conducted in a similar marine environment, copper alloy netting showed a significant reduction in biofouling compared to traditional nylon nets. This means that the frequency of net cleaning can be significantly reduced, saving both time and money. Divers typically need to clean nylon nets every few months, but with alloy netting, this interval can be extended to years. Additionally, when cleaning is required, it is much easier as the organisms do not attach as firmly.

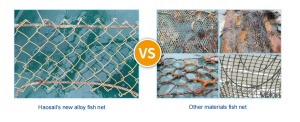

This image shows a comparison between a traditional nylon net heavily fouled with marine organisms on the left and a clean Haosail alloy net on the right, highlighting the anti-biofouling advantage.

Enhanced Strength and Durability

The harsh deep-sea environment, with its strong currents, high waves, and potential predator attacks, demands a netting material that can withstand extreme conditions. Haosail’s alloy netting is crafted from high-quality materials, providing exceptional strength and durability. The alloy is designed to resist wear and tear, even under constant exposure to the abrasive forces of seawater and the impact of waves. It has a much higher tensile strength compared to traditional polymer nets. This means that the net is less likely to break or tear, reducing the risk of fish escape. In areas with large predators like sea lions or sharks, the strong alloy netting can act as a reliable barrier, protecting the valuable fish stock. For instance, in some pilot projects in areas known for predator threats, fish farmers using Haosail alloy netting reported no incidents of net breaches by predators, while those using traditional nets faced multiple losses.

Excellent Corrosion Resistance

Seawater is highly corrosive, and traditional netting materials can degrade over time, leading to a reduction in their effectiveness and lifespan. Haosail’s alloy netting, on the other hand, is engineered to be highly corrosion-resistant. The materials used in its construction are carefully selected to withstand the harsh saltwater environment. Whether it’s the high salt content, fluctuating temperatures, or the presence of various chemical substances in the ocean, the alloy netting maintains its integrity. This not only ensures the long-term performance of the net but also reduces the need for frequent replacements. In a long-term study of netting materials in a deep-sea aquaculture site, Haosail’s alloy netting showed minimal signs of corrosion even after years of continuous use, while other traditional materials had significant rust and degradation.

Improved Water Exchange and Hydrodynamic Performance

Proper water exchange is essential for the health and growth of fish in aquaculture cages. The design of Haosail’s alloy netting allows for excellent water exchange. The net’s structure is optimized to minimize drag while maximizing the flow of water through the cage. This ensures that the fish are constantly surrounded by fresh, oxygenated water, which is crucial for their growth and well-being. In addition, the hydrodynamic properties of the alloy netting contribute to the stability of the cage in rough seas. The netting can better withstand the forces exerted by strong currents and waves, keeping the cage in place and reducing the risk of damage. For example, during a typhoon in a region where Haosail alloy netting was used, the aquaculture cages remained stable, while those with less hydrodynamic-friendly nets suffered significant damage.

Contribution to Sustainable Aquaculture

In an era where sustainability is a top priority, Haosail’s alloy netting aligns perfectly with the goals of the aquaculture industry. By reducing the need for frequent net replacements, the environmental impact associated with the production and disposal of traditional netting materials is minimized. The long lifespan of the alloy netting also means that fewer resources are consumed in the long run. Additionally, the anti-biofouling and corrosion-resistant properties contribute to a healthier marine environment by reducing the release of chemicals from antifouling coatings and preventing the leaching of corroded materials into the water. This promotes sustainable aquaculture practices and helps to protect the delicate balance of the ocean ecosystem.

In conclusion, Haosail Machinery’s high-definition alloy netting has the potential to significantly transform deep-sea aquaculture. Its unique combination of anti-biofouling, strength, corrosion resistance, and hydrodynamic performance makes it an ideal choice for fish farmers looking to improve the efficiency, productivity, and sustainability of their operations. As the demand for high-quality seafood continues to rise, the adoption of advanced technologies like Haosail’s alloy netting will be crucial for the continued growth and success of the deep-sea aquaculture industry.